Interview with our coordinator AIMPLAS

What is the role of your team in the implementation of LAURELIN?

Luis Iranzo Martínez: As coordinator, AIMPLAS is leading the managerial and technical coordination of LAURELIN project. I am in charge of the project management, meaning that I am responsible for reporting to the European Commission, the management of resources and risk assessment, and the smooth and effective execution of the tasks agreed by the consortium.

Dr. Adolfo Benedito is in charge of the project’s technical coordination. He leads the participation of AIMPLAS in all technical Work Packages (WPs) and is acting as the WP5 leader (Valorisation of CO2 by conventional thermal hydrogenation). He brings to the project his experience on the synthesis of catalysts based on materials such as Metal Organic Frameworks (MOFs) and Graphene Oxide-based materials (GOMs), and on microwave technologies. He has coordinated numerous regional, national and European projects related to Carbon Capture, Utilisation and Storage (CCUS) technologies.

Furthermore, Dr. Laura Martí and Dr. Monica Viciano support the technical implementation of the project, both of them are also experts in CCUS. Mr. Carlos Calvet provides managerial support on the coordination of the LAURELIN project.

Adolfo Benedito Borrás: As WP5 leader, we are setting up a traditional thermal reactor, where we can test a large part of the catalysts developed for the conversion of CO2 into e-methanol. This work will serve as a benchmark for the rest of the innovative reactors: microwave, low-temperature plasma, and magnetic induction reactors.

Could you please tell us more about the objectives of the project?

Luis Iranzo Martínez: The LAURELIN project is a H2020-LC-SC3-RES-25-2020 project under the topic “International cooperation with Japan for Research and Innovation on advanced biofuels and alternative renewable fuels.” The project received an EU Grant of €4.853.053 to develop, in cooperation with Japan, new catalysts and improve several synthesis technologies. This will improve in an efficient way how green hydrogen interact with CO2 to produce methanol.

Adolfo Benedito Borrás: LAURELIN aims to go beyond the current limits of CO2 conversion reactions from industrial emissions. Hydrogenation of CO2 into methanol suffers from important limitations, mainly related to selectivity. During hydrogenation, several undesired side-products, such as carbon monoxide, methane or ethanol, are produced at the same or higher level than methanol.

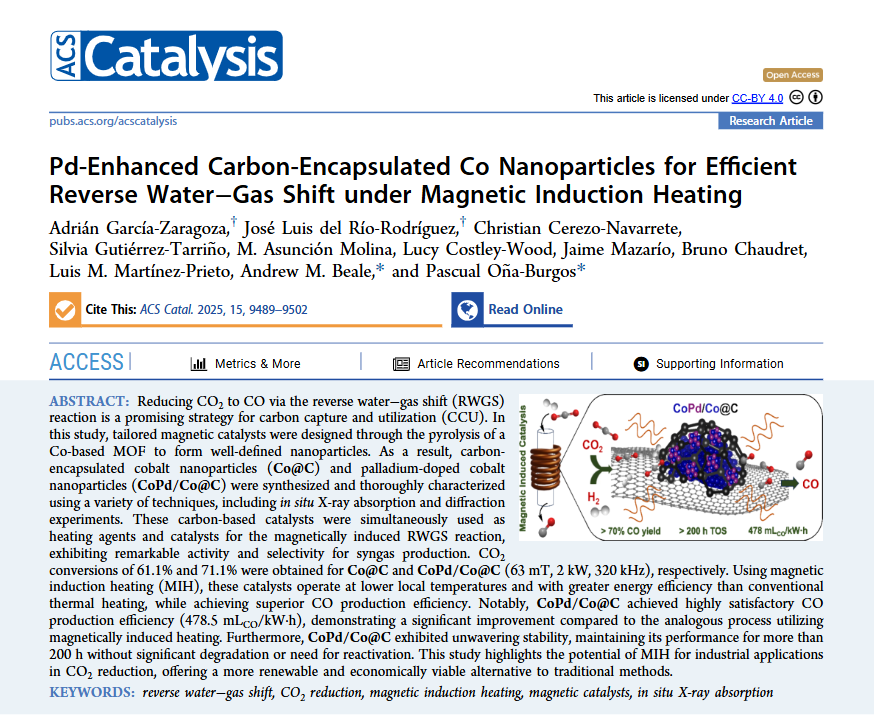

To avoid these problems, LAURELIN is committed to develop a new generation of promising catalysts that make the most of a new generation of chemical reactors: microwave, plasma and magnetic induction. Therefore, LAURELIN will foster breakthrough innovation in advanced biofuels and alternative renewable fuels, strengthening European and Japanese technology.

How and when was the idea of LAURELIN born? What was the need you identified which led you to launch LAURELIN?

Adolfo Benedito Borrás: As catalyst experts, the Instituto de Tecnología Química (ITQ-CSIC) and AIMPLAS are continually trying to solve the problem of the reactivity of the CO2 molecule. The potential of e-methanol as a fuel for the mobility sector can respond to important challenges for the next years. Thus, LAURELIN was born from the idea to take advantage of our background in catalyst and chemical reactors, and to seek to develop innovative processes to produce green methanol, achieving similar environmental impacts than the ones expected for the hydrogen industry.

Methanol is a biofuel that has many desirable attributes which make it an excellent spark-ignition engine fuel: high octane contribution, easy distillation, lower boiling temperature for better fuel vaporisation and improved efficiency. Furthermore, methanol obtained from industrial captured CO2 and green hydrogen can reduce carbon emissions by up to 95%. The transport sector not only need to reduce its greenhouse gas (GHG) emissions, but it also has to eliminate air pollutant emissions such as NOx and particulate matter, and be environmentally and economically sustainable.

LAURELIN presents a great opportunity to help achieving European energy objectives for 2030 and 2050.

What impacts do you expect the project to have on the methanol industry?

Luis Iranzo Martínez: We expect that one of the main impacts will be the improved exchange of knowledge through targeted research activities with Japan. This will help develop and improve the technology’s state-of-the-art and will strengthen the European and Japanese technology base.

It is expected that the development of renewable fuels that outperform the best fossil fuel alternatives will be accelerated. This is aligned with the Mission Innovation’s Challenge IC4 (Sustainable Biofuels) as we aim to reduce production costs and lower GHG emissions. Reducing the e-methanol production costs would lead to an increase in the opportunities to use it as fuel. This would directly benefits society thanks to the reduction in GHG emissions and costs, and would position Europe as a leader in methanol, creating further jobs and wealth.

How do you see the role of green methanol in decarbonising the transport sector?

Adolfo Benedito Borrás: Methanol has an impressive present and future as a fuel. Although methanol has a volumetric energy density lower than diesel and gasoline, it can act as an additive or substitute for gasoline in internal combustion engines to improve the octane number, with much lower emissions of hydrocarbons, NOx, SOx and soot. Moreover, renewable methanol cuts CO2 emissions by up to 95%, reduces NOx emissions by up to 80%, and completely eliminates SOx and particulate matter emissions. All the concerns about methanol risks or limitations, such as corrosivity, phase separation, energy content, fire risks or toxicity, can be easily solved today with the technology available while maintaining the current engine’s structure, only with minor changes.

Since road transport makes up almost two thirds of overall transport emissions, the use of renewable methanol as a fuel can reduce by more than 75% the GHG emissions. Developments are already underway across the world with China expanding its methanol economy and Nordic countries manufacturing methanol from biomass. A lot is happening!

After the first year of research, what would you highlight in the activities carried out until now?

Adolfo Benedito Borrás: During the first year of the project, we have analysed the problems linked to the synthesis of methanol from CO2. Catalysts are the key for methanol to become the main product, minimising the production of undesired complex mixtures. In addition, during this period, the innovative chemical reactors have begun to be designed, built, and even tested. Technical cooperation with Japanese colleagues is beginning to bear fruit in terms of team working and successful results!