Interview with our partner University of Manchester (UoM)

As part of our series of interviews of LAURELIN partners, it is the University of Manchester (UoM)‘s turn to give us an outlook of their role in the project. This interview offers you an unique glimpse into our cross-continental efforts driving progress within field of green production of methanol.

Why did the University of Manchester (UoM) join the LAURELIN project?

The University of Manchester joined the LAURELIN project to contribute to innovative solutions for environmental challenges.

The project focuses on converting carbon dioxide into valuable chemicals like green methanol using advanced, energy-efficient technologies such as non-thermal plasma and microwaves. This aligns with the university’s goals of promoting sustainability and achieving carbon neutrality. The collaborative nature of the project, involving leading experts from Europe and Japan, also offers Manchester a platform to be at the forefront of impactful research aimed at decarbonization and sustainable development.

What are the main activities undertaken by UoM in the framework of the project?

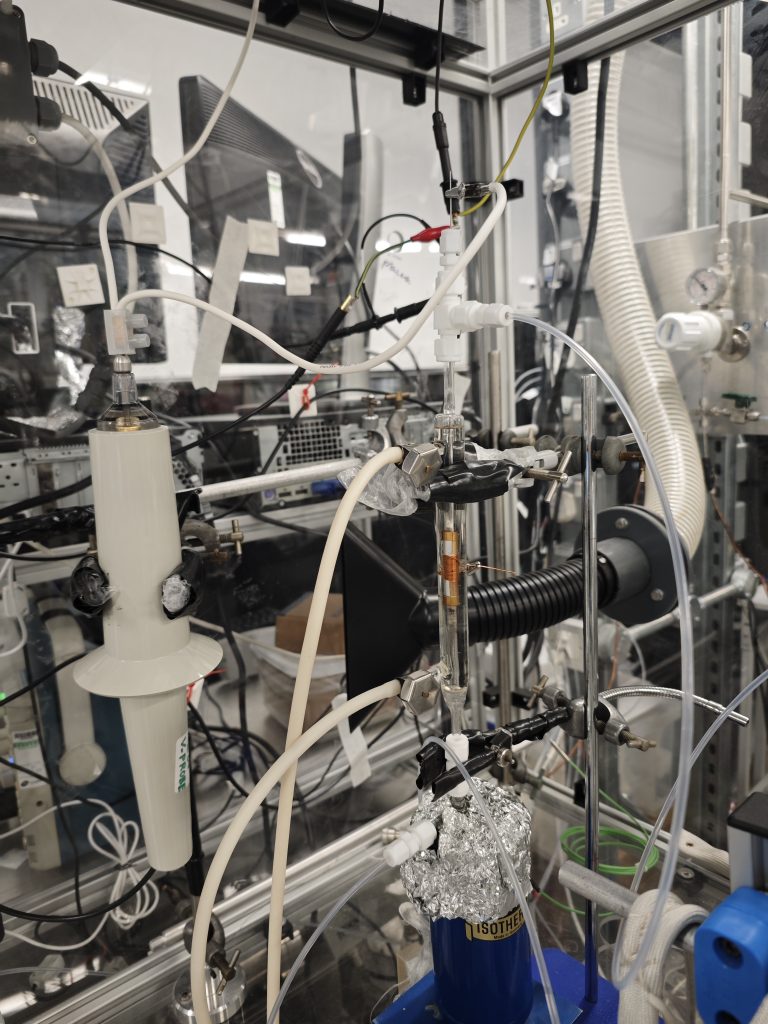

The University of Manchester’s expertise plays a pivotal role in the project, focusing primarily on the design and construction of a non-thermal plasma reactor for methanol production via CO2 hydrogenation. We engage in testing catalysts that are specifically designed for plasma-activated CO2 hydrogenation to methanol, sourced from different project partners.

Additionally, our efforts are directed towards optimizing plasma parameters such as power, voltage, and flow rate. This optimization aims to enhance the energy efficiency of the system, which could, in turn, reduce the environmental impacts associated with the production of renewable methanol.

Plasma reactor developed by UoM under the LAURELIN project

What are the challenges that you have identified to fulfill LAURELIN’s objective (the development of multifunctional and heterogeneous catalyst systems for efficient synthesis of renewable methanol)?

One of the primary challenges for the efficient synthesis of renewable methanol is optimizing the non-thermal plasma reactor for energy efficiency. Achieving a design that minimizes energy consumption while maximizing methanol yield is crucial and requires an intricate balance and tuning of operational parameters, including the use of a high-yield catalyst and varying the voltage supply to the reactors. To optimize this, we have applied the life cycle thinking concept by examining the primary energy demand for methanol production, ensuring that renewable methanol minimizes environmental impacts across its lifecycle.

Another significant challenge is scaling the reactor from laboratory to industrial scale. This scale-up involves maintaining the efficiency and effectiveness of the catalyst system while addressing the challenges of sustaining the plasma effect, which can impact overall reactor performance and methanol synthesis rates.

How important is the cooperation with your (European/Japanese) partners for the development of catalyst systems of renewable methanol?

Working with our European and Japanese partners is very important for creating catalyst systems to produce renewable methanol. These partnerships bring together different skills and new technologies that enhance our work. Our partners are experts in the manufacture and testing of catalysts, studying the mechanisms of how CO2 is converted into methanol, and designing future full-scale production plants. This expertise makes the process of producing methanol more efficient and effective. Collaborating with partners from different countries also allows us to share ideas and solve problems more effectively. By joining forces, we can develop better methods to produce renewable methanol, which helps us address environmental challenges and solve climate change issues.

To read the other interviews with our partners, see below.

- Interview with our partner Fraunhofer ICT

- Interview with our partner UCL

- Interview with our partner Process Design Center (PDC)

- Interview with our partner Tokyo University and Tokyo Tech

- Interview with our partner CSIC

- Interview with our project coordinator AIMPLAS

Media contact or for any further information: Cécile Fouquet – Aliénor: cecile.fouquet@alienor.eu